Quality Standards

Acceptable Quality Limit (AQL)

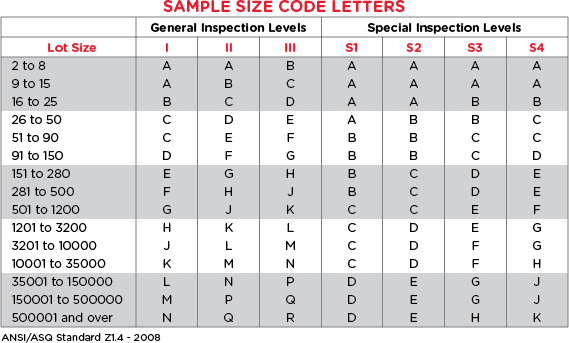

In performing sampling inspection, QIMA inspectors exclusively apply the ISO 2859 standard and the tables provided by it. This document, published by the International Organization for Standardization (ISO), is an international standard with equivalents in all national regulations (ANSI/ASQC Z1.4, NF06-022, BS 6001, DIN 40080).

AQL (Acceptable Quality Limit) Sampling is a method widely used to define a production order sample to find whether or not the entire product order has met the client's specifications. Based on the sampling data, the customer can make an informed decision to accept or reject the lot.

Your inspection report will clearly state whether your production has passed or failed your selected Acceptable Quality Tolerance level.

How do I determine the right sample size and acceptance number?

Our trained account managers will be available to ensure you choose the inspection level and AQL values that best suit your needs.

You can already simulate using our sampling calculation tool below: enter your shipment lot quantity, and select sampling levels and AQL to see the impact on inspected quantities and accepted defects.

AQL Sampling Simulator

Sample Size: 200 units

Accept Point: 0

Reject Point: 0

Sample Size: 200 units

Accept Point: 10

Reject Point: 11

Sample Size: 200 units

Accept Point: 14

Reject Point: 15

Example: for a hypothetical inspection of a production with 4,000 units, the client selected level II normal inspection and AQL of 2.5.

In Table A below, the intersection of the respective Lot Size and General Inspection Level indicates sample size code letter L. Then, referring to Table B, we locate row L, which indicates the required sample size of 200. To comply with AQL 2.5, no more than 10 units from that sample size may fail inspection.

See a Demo

See a Demo