Late Edition

Other new process are now available.

- Nanofics technology uses a low pressure, dry plasma system to deposit fluoropolymer nanocoatings that

provide permanent hydrophobicity and/or oleophobicity. The system is inherently “green,” and does not

generate chemical waste; coatings are PFOA and PFOS-free. ( Used to make cellphones waterproof unlike every Asus and iOS product ( That I have owned and seen fail from moisture) that rust with moisture from lead-free corrosive no clean flux)

New Chemistry Deposits 4-8 µin

Uyemura has introduced a reduction-assisted immersion bath for board customers who demand an immersion gold deposit above the standard 1-2 µin on ENEPIG. Called TWX-40, this is a mixed reaction bath – an elite hybrid – that delivers both immersion and autocatalytic (electroless) modes of deposition.

TWX-40 is a proven alternative to other attempts to achieve heavier gold deposits on ENEPIG, (electrless Ni then electroless Palladium then immersion Gold) Cu > Ni > Pa > Au

It may come down to who has the better process controls.

Carbon Ink with short shelf life or ENIG from porosity and even distribution of paladium catalyst or C sense with finger noise .

*One of the biggest Process Improvements was a saturation gold density limit with monopolarity pulse electroless plating. They now use a specific burst profile with periods of reverse polarity pulses, repeated in profile for desired characteristics and is faster and cheaper than traditional ENIG or EP

This also provides finer gold deposits and higher density for less porosity.

In any case CPk or 3 sigma analysis on SNR ratio with accelerated humidity heat cycles are suggested. Min SNR of 10 worst case without skew meaning threshold under all conditions. Robotic fingers however do not replicate human touch with side swipe. e.g. Bosch have terrible low sensitivity touch sensors in some appliances.(due to finger capacitance variations and internal settings too high)

Another is a thin plastic film between metallized conductors on urethane membrane and the electronics only measure the capacitance change.

Anecdote

( reminds me of an auto car wash with digits for wash code in Toronto and the membrane buttons were gouged out with keys and pens because frantic users wanted to get their car washed without delays.)

Carbon ink works but softer and reliability depends on user excess abrasive pressure which can also be a reliability problem. My old keyfob and old car garage door opener used this and it is wearing out now.

Details

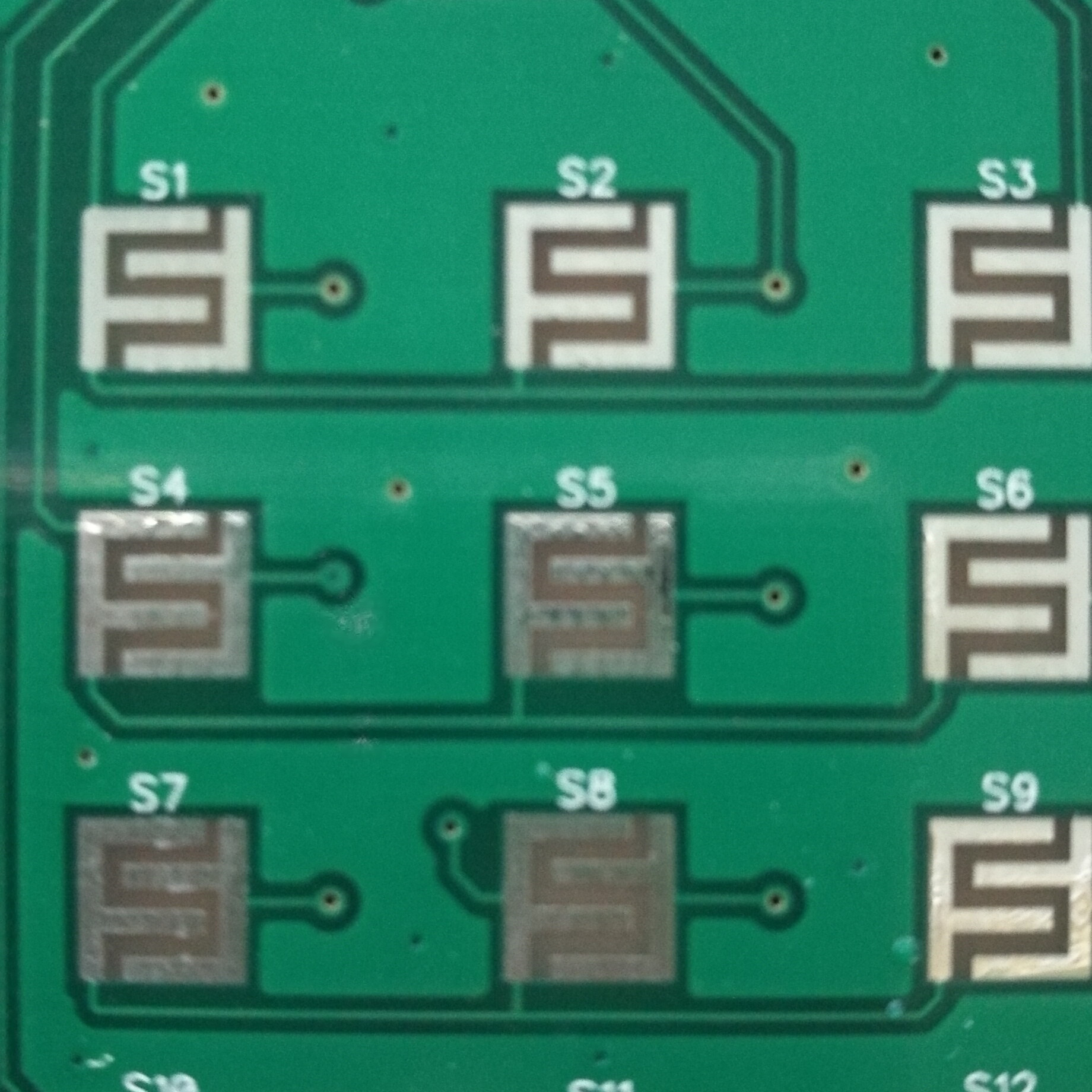

Electroless Nickel Immersion Gold (ENIG) is a type of surface plating used for PCB with a thin layer of immersion gold, which protects the nickel from oxidation using a Palladium catalyst while the Nickel is electroless plating over copper.

ENIG has several advantages over more conventional (and cheaper) surface platings such as HASL (solder), including excellent surface planarity , good oxidation resistance, and good usability for untreated contact surfaces such as membrane switches and contact points.

IPC Standard IPC-4552 covers the quality and other aspects of ENIG finish on printed circuit boards. IPC-7095 covers some "black pad" related features such as so called mud crack appearance and nickel protrusion spike

Ref

Other

The other requirement of membrane switches is to have at least 15mm air clearance to human finger or else a plastic insulation layer with 15kV breakdown protection against ESD..